By Carla Beaton, Pharmacist and VP of Quality Improvements and Innovations

Pharmacists across Canada fill more than 600 million prescriptions every year, and though somewhat rare, medication incidents do occur. When COVID-19 hit, it put unprecedented pressure on the industry. Virtually overnight, pharmacists were thrust to the frontlines of healthcare and overwhelmed with an influx of phone calls and visits from patients seeking reassurance, advice, and appointments for COVID-19 vaccinations and other health issues. Not surprisingly, as pressure mounted and labour shortages intensified, mistakes increased in certain areas.

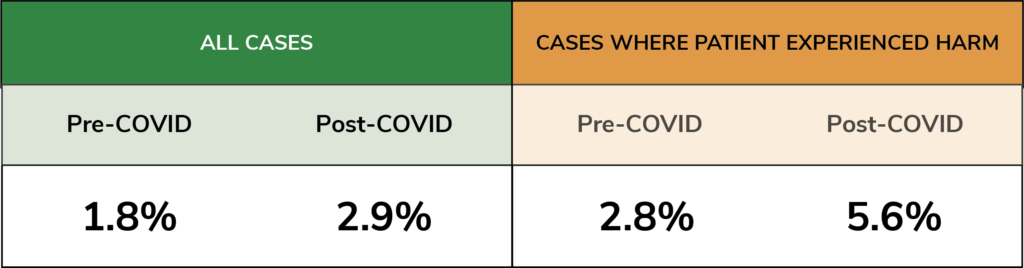

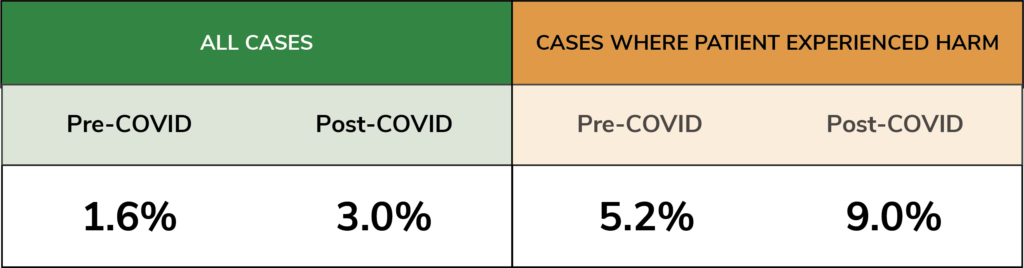

A study by Safe Assured on behalf of Pharmapod analyzed data representing more than 60,000 entries of medication errors and near-miss events from 65 percent of Canadian pharmacies pre- and post-COVID-19. They found that some areas of risk remained consistent with pre-COVID reporting, but as stress and workloads intensified in pharmacies throughout the pandemic, five areas of risk significantly increased and tended to be involved when harm occurred.

Here are the five categories of contributing risk factors that occurred in Canadian pharmacies throughout the pandemic – plus actionable items for limiting risk moving forward.

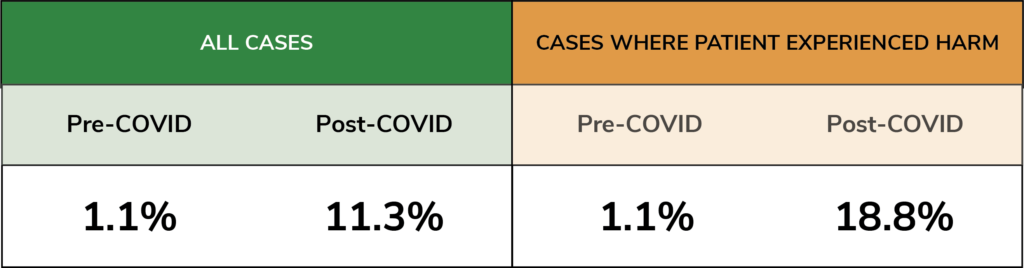

1. Environmental Distractions – OVER TENFOLD INCREASE

Environmental distractions were most often caused by:

- Numerous phone calls and inquiries about COVID, vaccinations, testing, etc.

- Influx of walk-in traffic , workload higher than normal

- Interruptions

- Multitasking beyond the usual process

Actionable Item: Online booking systems and standardized website information updates can help limit or divert phone calls to the pharmacy. Assign one employee to handle phone calls each day or to screen calls which can be delegated to the appropriate person. Manage customer/patient expectations – something the restaurant industry has mastered – by displaying wait times, busier than usual times of the day, dedicated immunization or clinical service times, and by implementing call or text when ready functions, and the ability to have the prescriptions delivered at a later time.

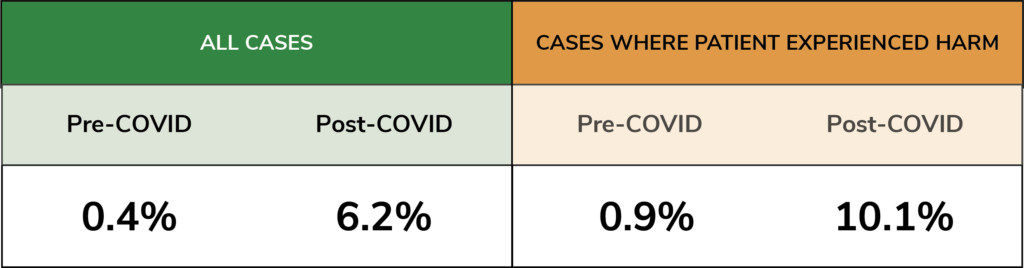

2. Operational Processes – TENFOLD INCREASE

Operational process errors were commonly caused by:

- Communication failures

- Missing or incorrect data entry

- Lack of clarity in policies and/or policies not followed

- System failures

- Timing disconnect or failure

- Inefficient or ineffective workflows

Actionable Item : As each pharmacy operates to accommodate their clientele, it is not a one-size-fits-all answer here. Control what you can. Complete a PSSA (Pharmacy Safety Self Assessment) to identify areas of risk and set goals to improve any gaps in your pharmacy.

Identify what needs to be escalated as systemic improvements requiring more stakeholders, including government, policy makers, professional associations, or management.

There are error prevention action plans that on the surface seem to provide the easiest and fastest solutions, however people cannot be expected to compensate for weak systems. Select high-leverage error prevention activities that are designed to fix the system, not just people, whenever possible.

Activities from highest leverage to lowest leverage include:

- Forcing functions and constraints

- Automation and computerization

- Drug protocols and standard order forms

- Independent double checks and other redundancies

- Rules and policies

- Education and information

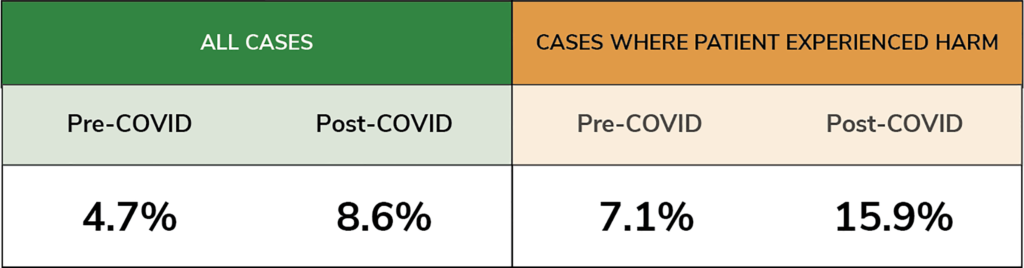

3. Drug Related Issues – DOUBLED

Examples of Drug related errors include:

- drug shortage, back order situation, drug recalled by manufacturer, lack of inventory

- multiple concentrations of the same drug, strength not commercially available

- unclear / absent labelling

- critical drug information missing (e.g. strength, duration, area )

- dangerous/ inappropriate abbreviations used

Actionable Item: Many of these elements are systemic and often beyond the pharmacy’s control (i.e., drug shortage / backorder / recall / strength not available / labelling ). Systemic fixes typically require outside stakeholders working toward a common goal to mitigate the risk. Pharmacies have workaround plans and procedures for people to handle this risk, however people will not eliminate the risk, only system changes can.

Concentrate on improving efficiencies you can control with workflows to avoid drug related issues. Start with measuring workflow and inventory flow to get a baseline you can work with. Implement a proper pharmacy layout so drug-related tools are at your fingertips or close to your workstation to make accessing/ordering inventory easier, addressing multiple concentrations safer, clarifying/obtaining missing information faster, and prevent unnecessary wasting of time. Automating inventory in your dispensing software provides staff time to complete other tasks and minimizes shortages you can control.

Electronic ordering of prescriptions can be programmed to avoid dangerous abbreviations and/or missing critical drug information. Work with prescribers to move to electronic ordering and have a verification check of each original, new and refill prescription.

4. Critical Patient Information Missing or Incorrect – DOUBLED

Examples of critical pieces of patient information missing include:

- medication history

- allergy information

- address

- lab values

- pregnancy status

- history of medical conditions

- information on renal or liver function

Actionable Item: It sounds simple, but when you’re feeling rushed, it’s critical to take a moment and ensure you inquire at each patient interaction about all necessary and relevant patient information. Create a checklist of essential questions to ask all patients – new and repeat – when filling prescriptions to ensure you are current with changes in their health status or location. Having an efficient workflow will reduce frustrations for both pharmacy staff and customers. Inefficient workflows result in increased wait times and can result in patients leaving the pharmacy without medication, or leaving the pharmacy without proper counselling.

5. Patient / Caregiver Education Issues – DOUBLED

Patient or caregiver education issues were most often caused by:

- Appropriate information not provided to patients or caregivers

- Lack of clarity when providing information

- Lack of understanding by patient or caregiver

Actionable Item: An estimated 60 percent of Canadian adults lack the health literacy skills needed to adequately manage their health, which can lead to difficulties comprehending medication information, misinterpretation of instructions, and/or poor adherence. Take the appropriate time to communicate effectively to ensure patients and/or their caregivers fully understand how to safely take their prescription. Work with your team to source written materials in the language your patients best understand (this could be a systems change). Study your workflow process to avoid multitasking as much as possible – this might mean delegating tasks to maximize on the scope of practice for registered pharmacy technicians and dedicating the necessary time for the pharmacist to deliver the appropriate patient and caregiver education.

Discuss the importance of improving pharmacy workflow efficiency in order to maximize pharmacist-patient interactions. As mentioned, patients who are frustrated with wait times or who do not understand what is being done for their safety behind the counter may end up leaving the pharmacy without their medication or without counselling on how to properly take the medication, which can have dangerous consequences to their health or result in unnecessary drug waste. Waste disrupts the inventory systems and leads to further workflow issues.

+ + +

Book a demo to learn more about how Pharmapod’s industry-leading platform can support your pharmacy’s medication and patient safety goals.

Want to see the full report? Join our mailing list to receive a copy in your inbox once available.

This article originally appeared on Canadian Healthcare Network. Pharmapod is a member of the Think Research family of companies.

Share this Article

Recent Articles

Why More Medication Incident Reports Indicates a Safer Pharmacy Environment

It’s a common misconception in pharmacies that having many medication incident reports indicates the pharmacy environment is unsafe. Actually, the opposite is true. The more

On-Demand Webinar: Pharmapod Safety Series – Creating Your Own Safety Net

From drug shortages to high volumes of walk-in traffic, environmental distractions are unavoidable in pharmacies – but they’re also the #1 contributing factor to medication

Think Research’s Pharmapod Adopted in University and Colleges Across Canada to Teach Foundations of Medication Safety

TORONTO, ON – February 27, 2024 – Think Research Corporation (TSXV: THNK) (“TRC” or the “Company“), a company focused on transforming healthcare through digital health